8

2024

-

10

Aluminum profiles flexibly meet various challenges, providing you with customized solutions!

In the fields of modern architecture and industrial manufacturing, the pursuit of quality and innovation has become an unwavering trend. lovelle aluminum profiles, with their excellent technical craftsmanship and outstanding design concepts, are providing lighter, stronger, and more aesthetically pleasing solutions for various industries. Whether in architectural projects aiming for ultimate appearance and durability or in industrial manufacturing requiring precision structures and flexible applications, lovelle aluminum profiles consistently deliver high-performance customized products to clients. Choosing lovelle means choosing efficient, environmentally friendly, and reliable aluminum profile solutions.

Aluminum profile ceilings are a type of ceiling material made from aluminum alloys through processes such as extrusion, cutting, and surface treatment. They are widely used in modern environments like commercial buildings, office spaces, and transportation hubs. Aluminum profile ceilings are popular due to their lightweight, corrosion-resistant, flexible design, and easy installation. Common forms include aluminum curtain walls, aluminum strip ceilings, aluminum grid ceilings, and aluminum clip-in ceilings.

Aluminum Curtain Wall

Aluminum curtain walls are a type of exterior wall decoration material used in modern architecture, primarily made from aluminum alloy. They offer advantages such as lightweight, high strength, corrosion resistance, and ease of processing. Aluminum curtain walls are commonly used in commercial, office, and public buildings, providing not only excellent decorative effects but also superior structural performance and functionality.

Features

Lightweight and High Strength: Aluminum curtain walls have a low density yet high strength, effectively reducing the overall load of the building, making them suitable for high-rise applications.

Strong Corrosion Resistance: The surface of aluminum alloy materials is treated with anodizing or spraying, which effectively resists corrosion from air, rainwater, and other chemical substances, extending their service life.

Good Thermal Insulation: Aluminum curtain walls are often designed with insulation materials, offering excellent thermal insulation performance that helps improve building energy efficiency.

Design Flexibility: The shape, color, and texture of aluminum curtain walls can be customized according to design requirements, allowing for a rich variety of aesthetic effects to meet different architectural styles.

Easy Maintenance: The smooth surface of aluminum curtain walls prevents dust accumulation, making cleaning and maintenance relatively simple, usually requiring only water and detergent for wiping.

Excellent Fire Resistance: Aluminum curtain walls have good fire-resistant properties, effectively resisting the spread of fire.

Classification

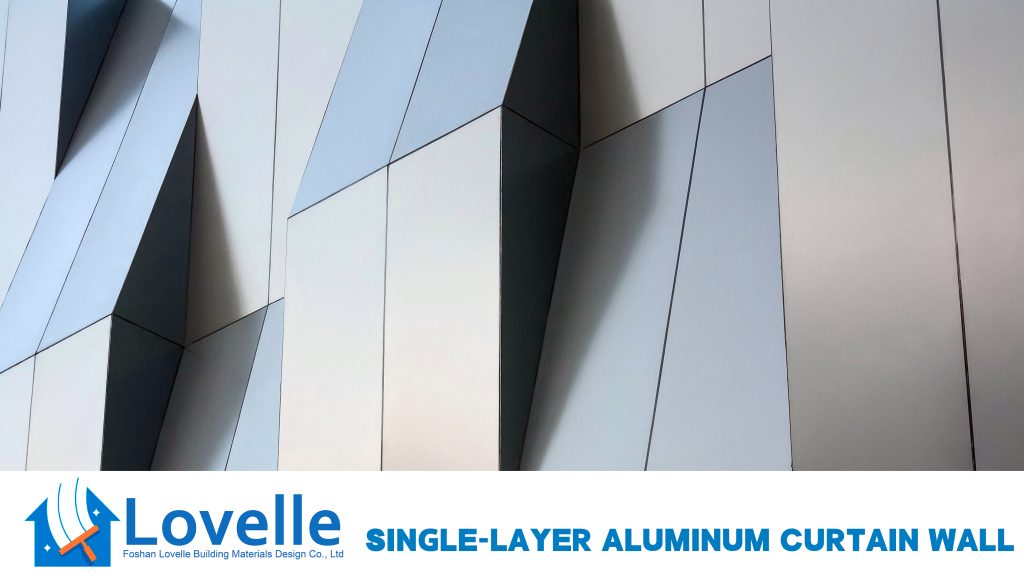

Single-Layer Aluminum Curtain Wall: Composed of single-layer aluminum alloy panels, typically used in low-rise buildings and some economic projects.

Composite Aluminum Curtain Wall: Made of two layers of aluminum alloy panels with insulation materials in between, providing better thermal insulation and soundproofing performance, suitable for high-rise buildings and energy-efficient projects.

Glass Aluminum Curtain Wall: Combines glass elements with aluminum curtain walls, forming a combination of aluminum frames and glass panels, offering a modern and transparent appearance, commonly used in commercial buildings and public structures.

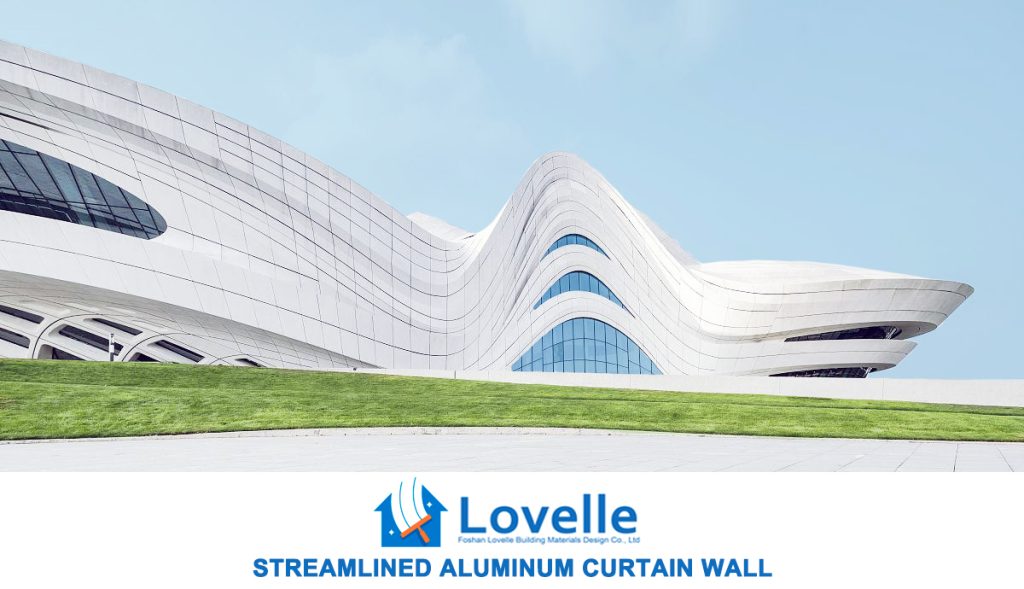

Streamlined Aluminum Curtain Wall: Features a streamlined design that presents a dynamic aesthetic, suitable for buildings with avant-garde designs.

Application Areas

Commercial Buildings: In shopping malls and office buildings, aluminum curtain walls create a modern and stylish appearance that attracts customers and tenants.

Public Buildings: In airports, train stations, museums, and other public structures, aluminum curtain walls provide expansive facades, enhancing the building’s aesthetics.

High-Rise Residences: In high-rise residential projects, aluminum curtain walls not only provide good sound insulation and thermal performance but also increase lighting and views.

Industrial Buildings: In factories and warehouses, aluminum curtain walls offer fire-resistant and corrosion-resistant solutions for exterior walls.

Installation Method

The installation of aluminum curtain walls generally involves an aluminum alloy keel support system, with the following steps:

Foundation Preparation: Ensure that the wall foundation is flat and secure.

Keel Installation: Install aluminum alloy keels on the wall according to design drawings, ensuring their verticality and flatness.

Curtain Wall Panel Installation: Fix the aluminum curtain wall panels to the keels using bolts, rivets, or other connection methods.

Sealing Treatment: Perform sealing treatment at the joints to ensure waterproof, windproof, and thermal insulation performance.

Surface Treatment

Surface treatments for aluminum curtain walls can include various processes, such as:

Anodizing: Enhances the corrosion resistance of the aluminum material, providing various colors and gloss levels.

Powder Coating: Uses electrostatic spraying technology to create an even coating on the aluminum surface, offering good wear resistance and decorative effects.

Fluorocarbon Spraying: Utilizes fluorocarbon coatings for surface treatment, providing higher weather resistance and stain resistance, suitable for buildings in extreme climate conditions.

Summary

Aluminum curtain walls, with their lightweight, durability, and aesthetic appeal, are widely used in modern architecture. They not only meet the diverse demands of building exterior design but also enhance energy efficiency and service life. With advancements in building technology, aluminum curtain walls will play an increasingly important role in building decoration and functionality.

Single-Layer Aluminum Curtain Wall

Single-layer aluminum curtain walls are an exterior wall system constructed from single-layer aluminum alloy panels, primarily used for the decorative and protective purposes of building facades. Compared to composite aluminum curtain walls, single-layer systems have a relatively simple structure and are typically suitable for low-rise buildings or projects with budget constraints. Below is a detailed introduction to single-layer aluminum curtain walls:

Features

Lightweight and High Strength: Single-layer aluminum curtain walls use aluminum alloy materials that are lightweight yet strong, effectively reducing the overall load of the building, making them suitable for low-rise and mid-rise structures.

Cost-Effective: Due to their simpler structure, production, and installation costs are relatively low, making them suitable for projects with budget constraints.

Corrosion Resistance: Aluminum alloy has good corrosion resistance, and after undergoing anodizing or spraying treatment, it can resist various environmental factors, extending its service life.

Design Flexibility: Single-layer aluminum curtain walls can be customized for different colors, textures, and shapes according to design needs, suitable for various architectural styles.

Easy Maintenance: The smooth surface of the aluminum curtain wall makes it difficult for dust to accumulate, and cleaning is simple, usually requiring just a damp cloth for wiping.

Good Fire Resistance: Aluminum alloy materials offer good fire resistance, effectively preventing the spread of fire.

Application Areas

Low-Rise Buildings: Suitable for schools, residential buildings, and commercial buildings, meeting basic decoration and protection functions.

Economic Buildings: Due to relatively low costs, single-layer aluminum curtain walls are often used in economic building projects such as affordable housing and low-rent apartments.

Commercial Buildings: In some cost-sensitive commercial buildings, single-layer aluminum curtain walls can provide a modern appearance.

Temporary Structures: Due to easy installation and simple structure, single-layer aluminum curtain walls are also commonly used in temporary buildings and exhibition halls.

Installation Method

The installation of single-layer aluminum curtain walls generally includes the following steps:

Foundation Preparation: Ensure that the wall foundation is flat and secure.

Keel Installation: Install aluminum alloy keels on the wall according to design drawings, ensuring their verticality and flatness.

Curtain Wall Panel Installation: Fix the aluminum curtain wall panels to the keels, usually using bolts, rivets, or other connection methods.

Sealing Treatment: Perform sealing treatment at the joints to ensure waterproof, windproof, and thermal insulation performance.

Surface Treatment

Surface treatments for single-layer aluminum curtain walls can include various processes, such as:

Anodizing: Enhances the corrosion resistance of the aluminum material, with the surface available in various colors and gloss levels.

Powder Coating: Uses electrostatic spraying technology to create an even coating on the aluminum surface, offering good wear resistance and decorative effects.

Fluorocarbon Spraying: Suitable for buildings that require long-term weather resistance, fluorocarbon coatings provide better weather and stain resistance.

Summary

Single-layer aluminum curtain walls, with their lightweight, durability, and cost-effectiveness, are widely used in low-rise and economic building projects. They not only provide basic decorative effects but also possess good corrosion resistance and fire protection features. With advancements in building technology, single-layer aluminum curtain walls will continue to play an important role, becoming an indispensable exterior wall system in modern architecture.

Composite Aluminum Curtain Wall

A composite aluminum curtain wall is an exterior wall system made up of two layers of aluminum alloy panels with insulating material in between. It provides excellent thermal insulation, soundproofing, and structural strength, making it widely used in high-rise buildings and projects with high energy efficiency requirements. Below is a detailed introduction to composite aluminum curtain walls:

Features

Excellent Insulation Performance: The insulating material (such as polystyrene, polyurethane, etc.) in the middle effectively reduces heat conduction, providing good thermal insulation and helping to save energy.

Good Soundproofing: The composite structure design minimizes the intrusion of external noise, making it suitable for urban environments and densely populated areas.

Lightweight and High Strength: The composite aluminum curtain wall is lightweight yet strong, able to withstand high wind pressure and other external forces, making it ideal for high-rise buildings.

Strong Corrosion Resistance: Aluminum alloy materials undergo anodizing or spraying treatment, ensuring good corrosion resistance and extending the lifespan of the curtain wall.

Design Flexibility: Composite aluminum curtain walls can be customized in various colors, textures, and shapes according to design requirements, meeting the needs of different architectural styles.

Easy Maintenance: The smooth surface of composite aluminum curtain walls resists dust accumulation, making them easy to clean and maintain; typically, only water and a cleaning agent are needed for maintenance.

Application Areas

High-Rise Buildings: In office buildings, hotels, and shopping malls, composite aluminum curtain walls provide good aesthetics and performance.

Public Buildings: Widely used in museums, exhibition centers, airports, and other public spaces, enhancing the modern feel and visual impact of the architecture.

Residential Buildings: In upscale residential areas, composite aluminum curtain walls improve the facade’s appearance and residents’ comfort.

Commercial Spaces: In shops and shopping centers, composite aluminum curtain walls create a pleasant shopping environment for customers and enhance the brand image.

Installation Method

The installation process for composite aluminum curtain walls typically includes the following steps:

Foundation Preparation: Ensure the wall foundation is level and solid, meeting installation requirements.

Framework Installation: Install aluminum alloy frameworks on the wall according to design drawings, ensuring the framework is vertical and level.

Curtain Wall Panel Installation: Fix the composite aluminum curtain wall panels to the framework using bolts, rivets, or other connection methods to ensure structural stability.

Sealing Treatment: Seal the joints to ensure waterproof, windproof, and thermal insulation performance.

Surface Treatment

The surface treatment of composite aluminum curtain walls can be done using various processes, including:

Anodizing: Enhances the corrosion resistance of the aluminum and offers a variety of colors and gloss levels.

Powder Coating: Forms a uniform coating on the aluminum surface through electrostatic spraying technology, providing good wear resistance and decorative effects.

Fluorocarbon Spraying: Offers higher weather resistance and dirt resistance, suitable for buildings in extreme climate conditions.

Summary

Composite aluminum curtain walls are widely used in modern architecture due to their excellent insulation, soundproofing, and aesthetic appeal. They not only meet diverse architectural design needs but also enhance the energy efficiency and lifespan of buildings. With advancements in construction technology, composite aluminum curtain walls will continue to play an important role in architectural decoration and functionality in the future.

Glass Aluminum Curtain Wall

A glass aluminum curtain wall is a modern building exterior system that combines an aluminum alloy frame with glass panels. It not only provides an elegant and contemporary appearance but also possesses excellent functionality, making it widely used in commercial buildings, office towers, hotels, and public structures. Below is a detailed introduction to glass aluminum curtain walls:

Features

Aesthetic Appeal: Glass aluminum curtain walls offer clear visibility and transparency, maximizing natural light and enhancing the beauty and modernity of the building.

Structural Strength: The lightweight yet robust aluminum alloy frame can withstand significant wind pressure and external loads, making it suitable for high-rise applications.

Thermal and Sound Insulation: The use of double or triple-glazed glass significantly improves thermal and sound insulation, helping to maintain a comfortable indoor temperature and environment.

Fire Resistance: Both glass and aluminum alloy materials have excellent fire resistance, effectively reducing fire risks.

Weather Resistance: Specially treated aluminum and glass surfaces can withstand rain, sunlight, and pollution, prolonging the lifespan of the curtain wall.

Easy Maintenance: The smooth surface of the glass makes it convenient for cleaning and maintenance, typically requiring only water and a cleaning agent.

Application Areas

Commercial Buildings: Glass aluminum curtain walls are commonly used in shopping malls, office buildings, and other commercial structures, attracting customers and enhancing brand image.

Public Buildings: In airports, museums, exhibition centers, and other public venues, glass aluminum curtain walls create an open and bright spatial atmosphere.

Hotels and High-End Residences: In hotel and upscale residential projects, glass aluminum curtain walls provide excellent lighting and an attractive appearance.

Industrial Buildings: In some industrial structures, glass aluminum curtain walls can provide a modern look while ensuring safety and protection.

Installation Method

The installation process for glass aluminum curtain walls generally includes the following steps:

Foundation Preparation: Ensure the wall foundation is level and stable, meeting installation requirements.

Framework Installation: Install aluminum alloy frameworks on the wall according to design drawings, ensuring the frameworks are vertical and level.

Glass Installation: Secure the glass panels to the aluminum alloy framework, typically using rubber strips or specialized connectors to ensure structural stability.

Sealing Treatment: Seal the joints to ensure waterproofing, wind resistance, and thermal insulation.

Surface Treatment

The surface treatment of glass aluminum curtain walls typically includes:

Anodizing: Enhances the corrosion resistance of the aluminum, providing various colors and gloss levels.

Powder Coating: Forms a uniform coating on the aluminum surface using electrostatic spraying technology, offering good wear resistance and decorative effects.

Glass Treatment: The glass surface can undergo tempering, sandblasting, coating, and other treatments to enhance its strength and functionality.

Summary

Glass aluminum curtain walls, with their modern appearance, structural performance, and functionality, are widely used in contemporary architecture. They not only meet diverse architectural design needs but also enhance the energy efficiency and lifespan of buildings. With continuous advancements in construction technology, glass aluminum curtain walls will continue to play a significant role in future architectural designs, becoming a highlight in building aesthetics.

Streamlined Aluminum Curtain Wall

The streamlined aluminum curtain wall is an architectural exterior system characterized by its unique design and shape, which present smooth curves and a dynamic aesthetic. This curtain wall not only offers an elegant appearance but also effectively withstands wind pressure, rain, and other external factors, making it widely applicable in modern buildings, especially those pursuing avant-garde and personalized designs. Below is a detailed introduction to streamlined aluminum curtain walls:

Features

Unique Aesthetic Appeal: The design of the streamlined aluminum curtain wall is inspired by the curves and flowing forms found in nature, imparting a sense of movement and modernity to buildings and enhancing their visual attractiveness.

Superior Aerodynamic Performance: The streamlined design effectively reduces wind resistance and minimizes the impact of wind pressure on the building, enhancing safety and stability.

Lightweight and High Strength: The aluminum alloy material is both lightweight and strong, allowing the streamlined aluminum curtain wall to significantly reduce the overall load on the building.

Good Weather Resistance: Aluminum alloy undergoes anodizing or coating treatments, providing excellent corrosion and weather resistance to withstand extreme climate conditions.

Excellent Thermal and Sound Insulation: Streamlined aluminum curtain walls can be customized with suitable insulation materials and glass types, offering superior thermal and sound insulation.

Design Flexibility: The streamlined aluminum curtain wall can be tailored to various shapes and colors based on architectural design requirements, accommodating different architectural styles.

Application Areas

Commercial Buildings: Streamlined aluminum curtain walls are commonly used in high-end shopping malls, hotels, and office buildings, enhancing the image and appeal of commercial spaces.

Cultural and Public Buildings: In museums, exhibition halls, and cultural centers, streamlined aluminum curtain walls can create a unique atmosphere that attracts visitors.

High-Rise Buildings: Due to their superior structural performance, streamlined aluminum curtain walls are suitable for high-rise buildings, capable of withstanding significant wind pressure and environmental challenges.

Artistic Buildings: In some artistic and innovative architectural projects, streamlined aluminum curtain walls can highlight the building’s unique design, becoming a focal point.

Installation Method

The installation process for streamlined aluminum curtain walls typically includes the following steps:

Foundation Preparation: Ensure the wall foundation is level and stable, meeting design specifications.

Framework Installation: Install aluminum alloy frameworks on the wall according to design drawings, ensuring vertical and horizontal alignment.

Curtain Wall Panel Installation: Secure the streamlined aluminum curtain wall panels to the framework using specialized connectors or rubber strips, ensuring structural stability.

Sealing Treatment: Seal the joints to ensure waterproofing and thermal insulation.

Surface Treatment

The surface treatment of streamlined aluminum curtain walls typically includes:

Anodizing: Enhances the corrosion resistance of the aluminum, providing various colors and gloss levels.

Powder Coating: Forms a uniform coating on the aluminum surface using electrostatic spraying technology, offering good wear resistance and decorative effects.

Fluorocarbon Spraying: Provides higher weather resistance and dirt resistance, suitable for buildings in extreme climatic conditions.

Summary

Streamlined aluminum curtain walls, with their unique design, superior performance, and aesthetic appeal, are widely applied in modern architecture. They not only meet the diverse needs of architectural design but also enhance the energy efficiency and lifespan of buildings. As architectural design and technology continue to evolve, streamlined aluminum curtain walls will play an important role in future building projects, becoming a highlight in architectural design.

Classification of Aluminum Profile Ceilings

Aluminum profile ceilings are mainly classified into the following categories:

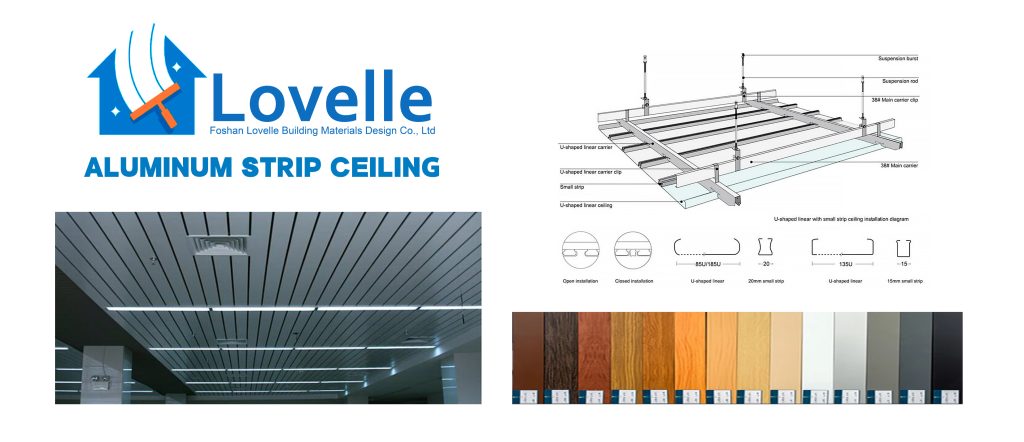

Aluminum Strip Ceiling: Also known as aluminum clip ceilings, these are made from strip-shaped aluminum profiles that are extruded and then clipped into a ceiling framework. They are commonly used in large spaces such as airports, train stations, and shopping malls. The width of the aluminum strips can be customized, resulting in a clean and smooth appearance with minimal gaps between panels, creating a seamless visual effect.

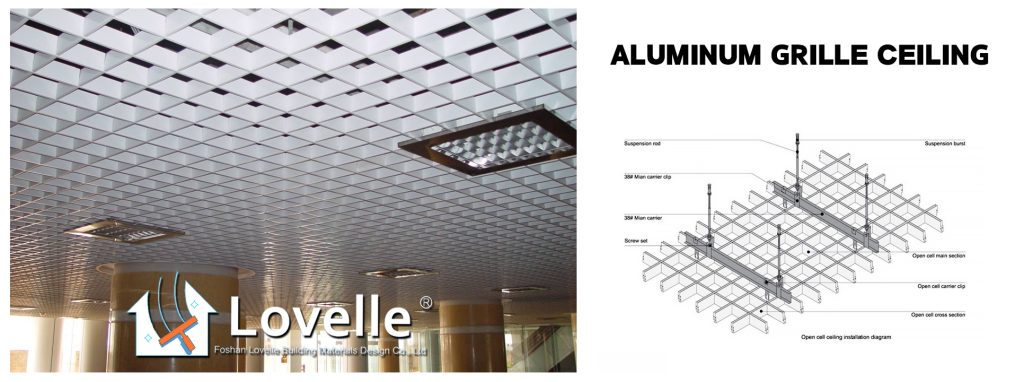

Aluminum Grid Ceiling: This type features an open grid structure made from aluminum materials, commonly used in areas that require ventilation and smoke exhaust, such as underground parking lots and subway stations. The design of aluminum grid ceilings is flexible and varied, effectively concealing overhead pipes and facilities while providing good visibility, preventing a sense of confinement in the space.

Aluminum Hanging Panel Ceiling: Constructed from aluminum materials in strip or panel form, these ceilings are fixed to the ceiling framework using hangers. They are commonly used in corridors and public transportation facilities. The design of aluminum hanging panel ceilings is simple with strong linearity, effectively hiding overhead installations while allowing for air circulation.

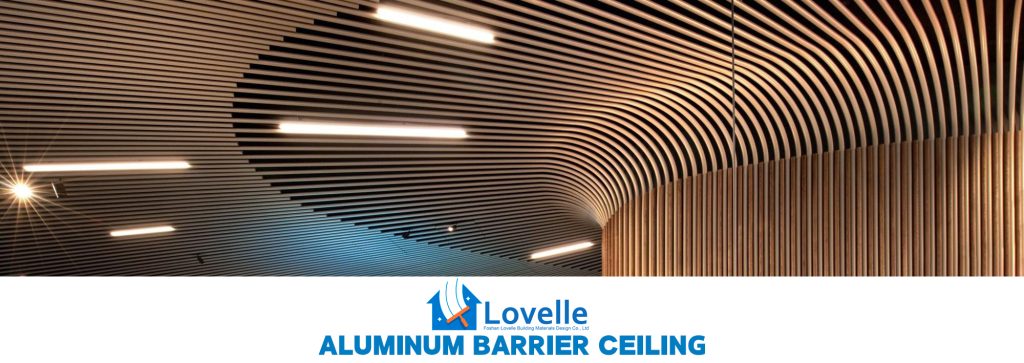

Aluminum Barrier Ceiling: Made from wider aluminum strips or sheet-like profiles, aluminum barrier ceilings are open and transparent, frequently seen in large areas such as airports and large shopping malls. They can obscure equipment above while maintaining air flow, resulting in a simple and modern visual effect.

Aluminum Square Panel Ceiling: Typically featuring square or rectangular modules, aluminum square panel ceilings are suspended for installation and are commonly used in public buildings, office buildings, and shopping malls. They are easy to install, provide a smooth surface, conceal overhead pipes and equipment, and have a modern, clean appearance.

Aluminum Square Panel Ceilings

Aluminum square panel ceilings are a common type of suspended ceiling material in architectural decoration. Made from aluminum alloy, they are precisely processed into square panels of various specifications and installed on ceilings using a framework system. Aluminum square panel ceilings are widely used in commercial, office, and public facilities due to their durability, lightweight, and aesthetic appeal.

Features of Aluminum Square Panel Ceilings

Lightweight and Durable: These ceilings are lightweight, making installation easy, and they have excellent durability and a long lifespan.

Good Corrosion Resistance: Aluminum possesses inherent oxidation resistance, and after surface treatment, it can resist acid and alkaline corrosion, making it suitable for humid environments like bathrooms and kitchens.

Various Surface Treatments:

Spraying: Electrostatic spraying technology allows for diverse colors and textures, meeting different design styles.

Rolling Coating: Rolling coated aluminum panels have a smooth, uniform surface with vibrant and long-lasting colors.

Film Coating: Some aluminum panels use PVC or metal film coating to enhance decorative and protective properties.

Design Flexibility: Aluminum panels can be customized in size, thickness, and color, making them adaptable to various design styles. Square panels can be combined with other geometric shapes or colors to create rich visual effects.

Fireproof, Moisture-Proof, and Sound-Insulating: Aluminum panels exhibit good fire resistance, are not easily ignited, and provide a degree of moisture-proof and sound insulation, making them suitable for public facilities and commercial buildings.

Easy to Clean and Maintain: The smooth surface resists dirt buildup and is easy to clean, particularly beneficial for spaces requiring regular maintenance.

Installation Method

Aluminum square panel ceilings are installed using a framework system, commonly employing T-type or concealed framework. During installation, the framework is first laid out, followed by embedding the aluminum panels to achieve a flat and visually appealing ceiling effect.

T-Type Framework Installation: The edges of the panels are exposed, forming a neat grid structure, commonly used in shopping malls and supermarkets.

Concealed Framework Installation: The framework is hidden behind the panels, with no visible seams on the surface, creating a stronger overall appearance, suitable for high-end locations and design-oriented spaces.

Applications of Aluminum Square Panel Ceilings

Commercial Spaces: Frequently used in shopping malls, supermarkets, and restaurants, aluminum square panel ceilings provide a durable and easy-to-clean ceiling decoration effect.

Public Facilities: Suitable for high-traffic areas like airports, train stations, and subways, thanks to their fireproof and moisture-proof properties.

Office Buildings: The modern appearance and clean design of aluminum square panel ceilings make them ideal for office environments.

Residential Spaces: High-end residences or villas may also incorporate aluminum square panel ceilings, particularly in kitchens and bathrooms where fire and moisture resistance are critical.

Advantages of Aluminum Square Panel Ceilings

Aesthetically Pleasing: The simple shape of aluminum square panel ceilings suits modern minimalist decor and can create rich visual effects through combination designs.

Moisture and Fire Resistant: The materials are moisture and fire resistant, especially suitable for bathrooms, kitchens, and other specialized environments.

Convenient Installation: Aluminum square panels are easy to install and remove, simplifying future maintenance and replacement.

Disadvantages of Aluminum Square Panel Ceilings

Higher Cost: Compared to standard gypsum boards or PVC materials, aluminum panels have a higher price point and initial investment.

High Technical Requirements for Installation: Although installation is quick, it requires skilled technicians to ensure the seams between panels are even.

Conclusion

Aluminum square panel ceilings are characterized by their excellent fire resistance, moisture-proof capabilities, and ease of cleaning, making them suitable for various building applications, particularly in environments that demand durability and low maintenance.

Aluminum Strip Ceiling

The aluminum strip ceiling is a type of ceiling decorative material composed of aluminum alloy strip panels, usually in a long strip shape, featuring a simple design and good practicality. It is widely used in commercial spaces, public facilities, and home decoration, particularly in environments with high requirements for moisture resistance, fire safety, and durability.

Features of Aluminum Strip Ceiling

Aesthetic and Simple: The aluminum strip ceiling presents a linear design with smooth lines, resulting in a neat and modern appearance when installed. It is suitable for minimalist and modern architectural styles, enhancing the spatial layering and extension.

Lightweight and Durable: Made from aluminum alloy, the aluminum strip ceiling is lightweight yet sturdy, with a long service life and resistance to impact. It does not deform or corrode in humid environments, making it particularly suitable for areas with high humidity, such as bathrooms and kitchens.

Fire and Moisture Resistant: Aluminum strips have excellent fire and moisture resistance. The surface-treated aluminum alloy effectively resists oxidation and is not prone to rust or corrosion, making it suitable for damp environments and buildings with high fire safety requirements.

Customizable Dimensions: Aluminum strip ceilings can be processed into different widths, lengths, and thicknesses according to project requirements, making them flexible for various spatial designs.

Rich Surface Treatments:

Electrostatic Spraying: Various color options are available as needed, with good wear resistance and lasting color.

Film Lamination: Some aluminum strip ceilings are covered with a PVC film or other decorative film to enhance durability and decorative effect.

Roll Coating: Roll-coated aluminum strip ceilings feature a smooth and uniform surface, maintaining consistent color.

Good Sound Absorption: With special design, aluminum strip ceilings can provide some sound absorption capabilities, making them particularly suitable for noise-sensitive areas such as conference rooms and libraries.

Installation Methods for Aluminum Strip Ceiling

The installation of aluminum strip ceilings is very flexible, typically fixed with a keel system and using a clip-on installation method. The aluminum strip panels are directly clipped into the pre-installed keel slots, ensuring tight seams and ease of disassembly and replacement.

Exposed Frame Installation: The keel is exposed, and the aluminum strips are embedded within, forming an open ceiling structure.

Concealed Frame Installation: The keel is hidden behind the strip ceiling, making the surface more flat and simple, with no obvious seams for a unified visual effect.

Combination Design: Aluminum strip ceilings can be installed using panels of different widths and colors to create a personalized decorative style.

Applications of Aluminum Strip Ceiling

Commercial Spaces: Widely used in shopping malls, supermarkets, and office buildings, aluminum strip ceilings can create a clean, modern spatial experience.

Public Facilities: In airports, subway stations, and hospitals, aluminum strips are commonly used for ceiling decoration due to their fire-resistant, moisture-resistant, and durable properties.

Residential Spaces: Particularly ideal for kitchens and bathrooms, where moisture and fire resistance are critical.

Large Buildings: In places with high requirements for ceiling materials, such as convention centers and sports arenas, aluminum strip ceilings provide an aesthetic yet practical solution.

Advantages of Aluminum Strip Ceiling

Simple Installation: The clip-on installation method allows for easy assembly and disassembly, enabling the easy replacement of individual panels as needed.

Fire and Moisture Resistance: The material itself has excellent fire-resistant properties and effectively prevents moisture infiltration, making it very suitable for humid environments.

Aesthetically Pleasing: The simple lines of the aluminum strip ceiling create a neat and grand effect in space, particularly suitable for modern minimalist design.

Strong Durability: The sturdy aluminum alloy material is durable and resistant to deformation, providing a long service life and reducing maintenance costs.

Environmentally Friendly and Recyclable: The aluminum alloy material is environmentally friendly and recyclable, aligning with modern sustainable building concepts.

Disadvantages of Aluminum Strip Ceiling

Design Limitations: Primarily linear in design, while the lines are simple, the capability for complex patterns and shapes is relatively limited.

Higher Cost: Compared to traditional ceiling materials such as gypsum board and PVC board, aluminum strip ceilings have higher material and installation costs, especially for large-scale applications.

Strong Sound Reflection: Although special designs can enhance sound absorption, aluminum material can produce sound reflection, potentially affecting the acoustic quality of the space.

Conclusion

Due to its characteristics of fire resistance, moisture resistance, durability, and ease of maintenance, aluminum strip ceilings have become a commonly used ceiling material in modern architectural decoration. They are especially suitable for commercial, public, and residential spaces that require high moisture and fire safety. With their simple and aesthetic linear design and flexible installation methods, aluminum strip ceilings meet the demands of projects seeking modernity and practicality.

Aluminum Grille Ceiling

The aluminum grille ceiling is an open ceiling system made of aluminum alloy, presented in a grid or lattice form, providing a transparent and three-dimensional decorative effect. Due to its unique grid design, the aluminum grille ceiling not only meets decorative needs but also offers excellent ventilation and lighting effects, making it widely applicable in various commercial, public, and industrial settings.

Features of Aluminum Grille Ceiling

Good Transparency: The aluminum grille ceiling is composed of interlaced aluminum strips forming a grid structure, allowing for open design that maintains ventilation, lighting, and air circulation. It is suitable for spaces requiring good airflow or transparency.

Aesthetic Appeal: With a clean and modern linear design, the aluminum grille ceiling provides a strong sense of three-dimensionality and layering, enhancing the decorative effect of the space. It can be combined with lighting to create rich visual effects.

Lightweight and Durable: Made from aluminum alloy, the aluminum grille ceiling is lightweight yet strong, with excellent corrosion resistance, durability, and impact resistance, maintaining its original shape and color over time.

Fire and Moisture Resistant: The aluminum alloy material is non-combustible and not easily affected by moisture, making the aluminum grille ceiling suitable for environments with high fire and moisture resistance requirements, such as kitchens, bathrooms, and garages.

Easy Installation and Maintenance: The modular design of the aluminum grille ceiling allows for quick installation and disassembly, facilitating later maintenance and repairs. The modular approach also makes it easier to replace damaged ceiling sections.

Diverse Options: The specifications, grid sizes, colors, and surface treatments of aluminum grille ceilings can be customized according to project needs, catering to different styles and functional design requirements. Common surface treatments include electrostatic spraying, film lamination, and anodizing.

Advantages of Aluminum Grille Ceiling

Good Ventilation and Lighting: The open grid design allows air and light to penetrate, making it ideal for spaces that require good airflow or lighting, such as garages, airports, and stations.

Excellent Decorative Effect: The aluminum grille ceiling has a sense of three-dimensionality and layering. Its simple grid lines are suitable for modern minimalist or industrial designs, enhancing the aesthetic appeal of the space.

Fire and Moisture Resistance: Aluminum alloy inherently has fire and moisture-resistant properties, making it particularly suitable for environments with high temperatures and humidity or stringent fire safety requirements.

High Flexibility: Different grid sizes, colors, and installation methods can be selected based on specific project needs, making it suitable for customized designs to meet diverse client requirements.

Convenient Maintenance: The open design of the aluminum grille ceiling facilitates maintenance and repair of air conditioning, ventilation, and fire protection equipment without the need to remove the entire ceiling.

Installation Methods for Aluminum Grille Ceiling

The aluminum grille ceiling is installed using a keel system, typically employing a modular assembly method. After the aluminum strips are processed and formed in the factory, they are fixed on-site using pre-fabricated clips and a keel system.

Exposed Frame Installation: The keel system is visible, and the aluminum strips are directly clipped into the keel, allowing for easy installation and removal.

Concealed Frame Installation: The keel system is hidden behind the ceiling, providing a more streamlined and flat overall appearance.

Suspended Installation: The aluminum grille ceiling can be suspended from the building structure using steel cables or hangers, creating a floating visual effect, suitable for large space decoration.

Applications of Aluminum Grille Ceiling

Commercial Spaces: Aluminum grille ceilings are commonly used in shopping malls, supermarkets, and exhibition halls, where the open design helps optimize lighting and ventilation and enhance the overall aesthetic of the space.

Public Buildings: In transportation hubs such as airports, subway stations, and train stations, where crowd density is high and air circulation and fire safety requirements are significant, aluminum grille ceilings effectively meet these needs.

Industrial Factories: In some industrial plants or workshops, aluminum grille ceilings provide both fire and moisture resistance while ensuring good ventilation and heat dissipation.

Underground Parking: Aluminum grille ceilings are widely used in underground parking garages, as their transparency allows smoke to dissipate quickly and facilitates the installation of ventilation and fire protection equipment.

Office Buildings: In modern office buildings, aluminum grille ceilings are often used for ceiling decoration due to their simplicity and beauty, along with ease of maintenance.

Advantages of Aluminum Grille Ceiling

Simple Shape with Strong Lines: The design of aluminum grille ceilings is very simple, suitable for modern architectural decoration, especially in industrial or minimalist spaces.

Good Ventilation and Smoke Exhaust: The open grid structure allows smoke and heat to dissipate quickly, making it suitable for underground garages and industrial plants.

Easy Subsequent Maintenance: The open design of the ceiling makes the maintenance and repair of air conditioning, ventilation, and fire protection systems relatively straightforward.

Strong Durability: The corrosion resistance and aging resistance of aluminum are robust. After surface treatment, they can be used for a long time without fading, deforming, or being damaged.

Disadvantages of Aluminum Grille Ceiling

Weak Insulation and Heat Preservation: Due to the open design of the aluminum grille ceiling, it does not have good insulation and heat preservation capabilities, making it unsuitable for environments with high temperature control requirements.

Poor Coverage Effect: The grid structure is relatively transparent and cannot completely cover the facilities and pipelines above the ceiling. If hiding the facilities is necessary, additional covering methods may need to be implemented.

Conclusion

With its excellent ventilation, durability, and aesthetic appeal, the aluminum grille ceiling is widely applied in various commercial and public spaces. Its lightweight, durability, and ease of installation and maintenance make it a popular choice in modern architecture. For spaces that require an open design, good ventilation, and smoke exhaust effects, the aluminum grille ceiling is an ideal option.

Aluminum Clip-in Ceiling

Aluminum clip-in ceilings are decorative ceiling materials made from aluminum alloy, typically installed in strips or panels that hang from a framework, creating a unique sense of linearity and spatial layering. Due to their modern minimalist design, good ventilation, and ease of installation, they are widely used in large spaces such as shopping malls, stations, and airports.

Characteristics of Aluminum Clip-in Ceilings

Strong Linear Effect: Aluminum clip-in ceilings are installed in strips or panels, providing a distinct linear effect that can create vertical or horizontal decorative impacts, making them suitable for modern minimalist architecture, especially in spaces that require precise line design.

Good Openness: With an open design featuring gaps between the strips, aluminum clip-in ceilings maintain excellent ventilation and light transmission, ideal for spaces that require air circulation or light penetration.

Lightweight and Durable: Made from aluminum alloy, these panels are lightweight yet sturdy, exhibiting superior corrosion resistance and aging resistance, ensuring long-term stability even in harsh environments.

Fire and Moisture Resistant: Aluminum clip-in ceilings possess good fire resistance and moisture resistance. The aluminum material is non-combustible and is not easily affected by humidity, making it especially suitable for public buildings or humid environments, such as airports, subway stations, and restrooms.

High Customizability: The width, length, color, and surface treatment of aluminum clip-in ceilings can be customized according to project requirements, allowing flexibility to meet various spatial design needs. Common surface treatments include electrostatic spraying, lamination, and anodizing.

Sound Absorption: Different shapes and installation methods of the panels can provide sound absorption capabilities, helping to improve the acoustic performance of the space.

Installation Methods for Aluminum Clip-in Ceilings

Aluminum clip-in ceilings are installed by hanging them using a framework system, forming a tidy strip ceiling. The installation method is flexible, making future maintenance and replacement easy.

Modular Installation: The aluminum clip-in ceiling system features a modular design, with clips or screws used to secure the panels to the framework, making installation and removal straightforward. Each panel can be replaced or maintained individually without removing the entire ceiling.

Framework System: The ceiling is supported and fixed by a framework system, with adjustable spacing and height according to design requirements to achieve different decorative effects.

Suspended Installation: In high spaces, aluminum clip-in ceilings can be suspended from the building structure using hanging devices, creating a floating effect for a lighter visual appearance.

Advantages of Aluminum Clip-in Ceilings

Excellent Decorative Effect: Aluminum clip-in ceilings create a strong sense of linearity and layering, resulting in a modern aesthetic ideal for large decorative projects such as malls, stations, and airports.

Ventilation and Light Transmission: The open installation method allows for free air circulation and light penetration, particularly suitable for spaces that require airflow or natural lighting.

Easy Maintenance: Installation and removal of aluminum clip-in ceilings are very convenient. The modular design facilitates easier maintenance and repair, reducing upkeep costs.

Fire and Moisture Resistant: These ceilings are non-combustible and moisture resistant, making them highly suitable for environments with strict fire safety requirements or high humidity, such as public transport hubs and parking lots.

High Customizability: Aluminum clip-in ceilings can be diversified based on design needs, such as varying strip widths, spacing, colors, and surface treatments, catering to different decorative requirements.

Disadvantages of Aluminum Clip-in Ceilings

Limited Sound Insulation: Although aluminum clip-in ceilings have some sound-absorbing properties, their open design results in relatively weak sound insulation, making them unsuitable for areas requiring high levels of soundproofing.

Poor Concealment: The gaps between the strips do not completely conceal overhead pipes and equipment. Additional materials may be needed for complete coverage of ducts and equipment if necessary.

Design Limitations: The focus on linearity results in a relatively simple design. While visual effects can be enhanced through color and strip width variations, intricate pattern designs may be somewhat restricted.

Applications of Aluminum Clip-in Ceilings

Shopping Malls and Supermarkets: Widely used in large commercial spaces, aluminum clip-in ceilings provide good ventilation and lighting effects while maintaining a modern decorative appearance.

Transport Hubs: In airports, stations, and subway stations, aluminum clip-in ceilings are extensively used due to their fire and moisture resistance, easy maintenance, and modern minimalist design.

Office Buildings: Commonly used in corridors and public areas of office buildings, they help create a modern office environment with a clean and elegant appearance.

Industrial Plants and Garages: Their fire-resistant and durable properties make aluminum clip-in ceilings suitable for industrial plants and underground garages that require fire safety and ventilation.

Leisure Venues: Ideal for cinemas, gyms, exhibition halls, and other places that need aesthetic appeal and sound absorption, aluminum clip-in ceilings are also an excellent choice.

Conclusion

Aluminum clip-in ceilings are functional and decorative ceiling materials that offer a sleek linear design and good ventilation performance. They are widely used in various large spaces due to their easy installation, fire and moisture resistance, and low maintenance requirements. In these settings, aluminum clip-in ceilings provide both aesthetic visual effects and practical functionality.

Aluminum Barrier Ceiling

The aluminum barrier ceiling (also known as aluminum sunshade ceiling or aluminum screen ceiling) is a modern decorative ceiling primarily made of aluminum alloy. It consists of strips, panels, or grid-like aluminum materials installed on the ceiling, featuring an open and ventilated design that provides privacy while maintaining air permeability. It is commonly used in public buildings, large shopping malls, and office buildings, creating a minimalist and stylish visual effect.

Features of Aluminum Barrier Ceiling

Open Design: The aluminum barrier ceiling uses strips or panels, forming an open structure that ensures good air circulation without obstructing the layout of overhead facilities such as air conditioning and lighting equipment.

Strong Modern Aesthetic: With a simple and stylish appearance and smooth lines, the aluminum barrier ceiling meets the demands for minimalist decor in modern architecture. It can adapt to various architectural styles through color and shape variations, creating a fashionable atmosphere.

Combination of Privacy and Transparency: The design of the aluminum barrier ceiling balances privacy and transparency, effectively concealing overhead pipes and equipment while maintaining a sense of openness, preventing the space from feeling too enclosed.

Lightweight and Durable: Aluminum alloy is lightweight yet strong, offering excellent corrosion resistance and durability, allowing for long-term use in various environmental conditions without rusting, deforming, or fading.

Fire and Moisture Resistant: Aluminum alloy inherently possesses fireproof and moisture-resistant properties, making it particularly suitable for areas requiring high fire safety standards and those with high humidity, such as airports, subway stations, train stations, and parking lots.

Flexible Design Options: The aluminum barrier ceiling can be customized according to project needs, allowing for various strip, grid, and panel designs. It can also undergo different color treatments such as spraying, film coating, and anodizing to meet diverse design requirements.

Sound Absorption: The aluminum barrier ceiling can help control acoustic effects within a space, reducing echoes and noise. It is often used as part of acoustic design in places like cinemas, concert halls, and conference rooms.

Advantages of Aluminum Barrier Ceiling

Aesthetic Concealment: The aluminum barrier ceiling effectively hides overhead pipes and equipment while maintaining a light and visually appealing atmosphere.

Ventilation and Natural Light: Its open design ensures good ventilation and can be combined with lighting to create a soft light effect, suitable for buildings that require natural light and airflow.

Easy Installation and Maintenance: The modular design of the aluminum barrier ceiling allows for simple installation and easy disassembly and replacement, facilitating maintenance and cleaning.

Fire and Moisture Resistance: The aluminum material has natural fireproof and moisture-resistant qualities, making it an ideal choice for areas requiring fire safety and environmental durability.

Design Flexibility: It allows designers to choose different shapes, sizes, and surface treatments, offering a wide range of design options to suit various architectural styles.

Eco-Friendly Material: Aluminum alloy is recyclable, reducing construction waste and material loss.

Installation Methods of Aluminum Barrier Ceiling

The installation of aluminum barrier ceilings is generally flexible and usually employs either suspended or grid-fix methods:

Suspended Installation: Aluminum barrier ceilings are suspended from the building structure using hanging pieces, creating an independent decorative effect. The height of the hangers can be adjusted according to spatial requirements.

Grid-Fix Installation: The aluminum barrier ceiling can be installed using a grid system, with the spacing and height of the grid adjustable based on design requirements. The strips are secured to the grid using clips or screws for easy installation and disassembly.

Application Scenarios of Aluminum Barrier Ceiling

Public Transport Facilities: Widely used in the decoration of airports and subway stations, aluminum barrier ceilings provide a modern, minimalist aesthetic while offering practical functions such as fireproofing, moisture resistance, and ventilation.

Shopping Malls and Exhibition Halls: In large shopping malls and exhibition centers, aluminum barrier ceilings create a fashionable, modern decorative effect while effectively concealing various overhead pipeline facilities.

Office Buildings and Conference Rooms: Commonly used in office buildings and conference rooms, aluminum barrier ceilings enhance the aesthetic appeal of the space while providing sound absorption to reduce indoor noise and improve comfort.

Industrial Plants: In industrial settings, aluminum barrier ceilings ensure good air circulation while concealing pipelines and equipment, maintaining a clean spatial feel, and providing durability and corrosion resistance.

Parking Lots and Underground Spaces: Aluminum barrier ceilings are frequently used in parking garages and underground spaces, with their open design facilitating ventilation and smoke exhaust while hiding overhead equipment and pipelines for a tidy visual effect.

Disadvantages of Aluminum Barrier Ceiling

Limited Sound Insulation: Due to its open design, the aluminum barrier ceiling offers some sound absorption but has weaker sound insulation compared to closed ceiling materials.

Weak Concealment: While it can hide some facilities, the open structure does not completely conceal all pipes and equipment, making it suitable for spaces where concealment is not a high priority.

Conclusion

The aluminum barrier ceiling is a modern ceiling material that combines functionality and decoration. Its minimalist design, transparency, and excellent fire and moisture resistance make it widely applicable in shopping malls, office buildings, airports, and other spaces. It can serve as a concealing structure while also providing an aesthetically pleasing decorative effect. With its easy installation and strong durability, it meets the dual demands of aesthetics and practicality in contemporary architecture.

Aluminum Specialty Ceiling

Aluminum specialty ceilings are ceilings made from aluminum alloy materials that feature unique shapes and design styles. Due to their distinctive appearance, excellent performance, and flexible design, these ceilings are widely popular and are commonly found in commercial, public, and cultural spaces.

Features

Design Flexibility: Aluminum specialty ceilings can be customized into various shapes and sizes based on design needs, such as curves, waves, and geometric shapes, making them adaptable to different decorative styles.

Lightweight and High Strength: Aluminum alloy materials are lightweight yet strong, making them suitable for large-area ceiling installations and effectively reducing the building’s load.

Corrosion Resistance: After surface treatment (such as anodizing or electrophoretic coating), aluminum alloys exhibit excellent corrosion resistance, making them suitable for humid environments.

Eco-Friendly and Recyclable: Aluminum profiles are renewable resources, aligning with modern construction’s requirements for eco-friendly materials and helping to reduce construction waste.

Easy Maintenance: The smooth surface of aluminum specialty ceilings does not easily accumulate dust, making cleaning and maintenance simple, usually requiring only a damp cloth.

Good Fire Resistance: Aluminum alloy materials possess good fire-resistant properties, making them suitable for areas with strict fire safety requirements.

Types

Aluminum Curved Ceiling: Made from aluminum materials, these ceilings are processed into curved shapes and are commonly used in spaces that prioritize smooth lines and a modern feel, such as luxury hotels and exhibition halls.

Aluminum Geometric Ceiling: Unique geometric shapes are constructed using aluminum profiles, adding interest and modernity to spaces, making them suitable for trendy commercial and cultural venues.

Aluminum Decorative Strip Ceiling: By combining aluminum decorative strips, this type of ceiling achieves a rich variety of shapes and layers, widely used in homes and offices.

Aluminum Grid Ceiling: This design features a grid pattern that enhances the ceiling’s transparency, making it ideal for spaces requiring good ventilation and light, such as underground parking lots and public transport facilities.

Application Areas

Commercial Spaces: In shopping malls, hotels, and other commercial buildings, aluminum specialty ceilings create a unique shopping and consumption experience, enhancing brand image.

Public Buildings: In public transport facilities like airports and subway stations, aluminum specialty ceilings improve the space’s transparency and modernity, accommodating high pedestrian traffic.

Cultural Venues: In museums, exhibition halls, and concert halls, aluminum specialty ceilings create unique artistic effects that attract visitors’ attention.

Office Environments: In modern office buildings, aluminum specialty ceilings foster an open and flexible work atmosphere, enhancing employee efficiency and comfort.

Installation Methods

The installation of aluminum specialty ceilings generally employs a grid support system, with common installation methods including:

Suspended Installation: Aluminum specialty ceilings are suspended from the grid system using hanging pieces, suitable for complex ceiling designs.

Direct Fixing: In some cases, aluminum specialty ceilings can be directly fixed to the substrate, suitable for small or simple shapes.

Surface Treatment Processes

Various surface treatments can be applied to aluminum specialty ceilings, including:

Anodizing: Enhances the corrosion resistance of the aluminum surface and can provide various colors and gloss levels.

Spray Coating: Electrostatic spraying forms a uniform coating with good wear resistance and decorative effects.

Wood Grain Transfer: Gives aluminum specialty ceilings a wooden appearance, suitable for designs that seek a natural and warm effect.

Conclusion

Aluminum specialty ceilings play an important role in modern architectural decoration due to their unique design and excellent performance. They not only meet diverse design needs but also possess characteristics such as lightweight, durability, and eco-friendliness. These ceilings are widely applied in commercial, public, and cultural spaces. With continuous innovation in design concepts, aluminum specialty ceilings will continue to play a significant role in spatial decoration.

Introducing Lovelle Construction Material Co., Ltd.: Your Comprehensive Source for Quality Building material and Interior Design Solutions.

At Lovelle Construction Material Co., Ltd., we are dedicated to providing top-notch building materials and exceptional interior design solutions. As a leading supplier in the industry, we pride ourselves on offering a wide range of products and services that cater to both construction professionals and homeowners. Our commitment to quality, innovation, and customer satisfaction sets us apart in the market.

Extensive Range of Building Materials from coating and painting for interior or exterior,ceiling gypsum board, porcelain tiles or ceramic tiles or sintered stone slab, wooden flooring, sanitary wares, shower head and faucet or taps, shower glass, toilet seat, kitchen cabinetry, wardrobe cabinetry, tv cabinetry, lighting chandelier, and sockets switch or lamps, aluminum windows or curtain walls and aluminum doors, wooden doors ,handles and smart locks,HDF doors, garage doors, natural marble or granite stone or quartz stone, wooden stair case or glass handrails, wall panel, home appliance like washing machine and cooker, home lift, fireplace,AC condition,curtain,solar system,etc.

Lovelle Construction Material Co., Ltd. offers an extensive selection of building materials to meet all your construction needs. Whether you’re looking for general construction supplies or specialized products, we have you covered:

Building Materials: From basic construction materials to advanced building solutions, we provide everything you need for your projects.

Construction Materials: Our products are sourced from top manufacturers to ensure durability and reliability.

Building Supplies: We offer a comprehensive list of building supplies available both online and in our building shop.Wholesale Construction Supplies: Benefit from our competitive pricing on wholesale building supplies for large-scale projects.

Convenient Online Shopping and Wholesale Options

Shopping for building materials has never been easier with our online platform. Lovelle Construction Material Co., Ltd. provides:

Building Supplies Online: Browse and purchase building materials from the comfort of your home , office , apartment, or hotel.

Building Materials Online: Our user-friendly website makes it simple to find and order the materials you need.

affordable Building Materials: We offer cost-effective solutions without compromising on quality.

Building Materials Wholesale: Get great deals on bulk purchases, perfect for contractors and large projects.

Direct and Factory Supply

Our direct supply chain ensures that you receive high-quality products at the best prices:

Building Materials Direct: Skip the middleman and purchase directly from us for significant savings.

Factory Direct Supply Company: We source our materials directly from manufacturers, ensuring consistent quality and availability.

Building Materials Manufacturers in China: We work with leading manufacturers in China to bring you the finest materials.

Related Products